Customer: SonntagPlus

CiMo Partner: FabLab Tirol

Challenge

Peatlands are unique habitats and play a central role in climate and species protection due to their enormous ability to store CO2. Despite these important characteristics, peatlands have a historically mysterious, almost menacing reputation. Their valuable importance is not easily recognizable to the viewer, as is the case, for example, with picturesque deciduous forests, wild river landscapes or habitats in the high mountains.

- Structure of a peatland

- Water storage

- CO2-Storage

- Drainage of a peatland and impact on the water balance

- Renaturation of peatlands

However, SonntagPlus had neither the resources nor the technological know-how to implement this idea, which has truly a very high impact level.

Methods

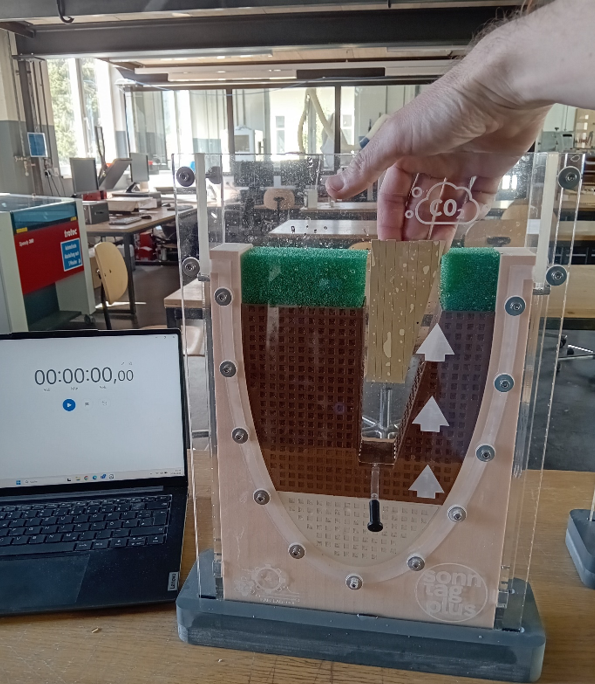

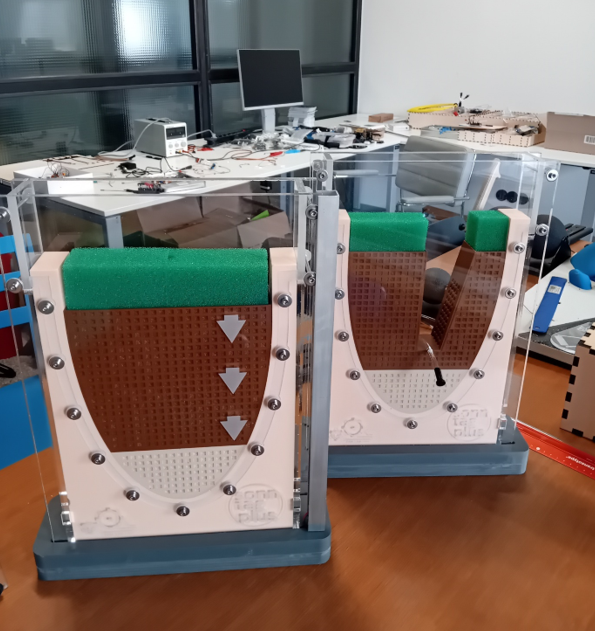

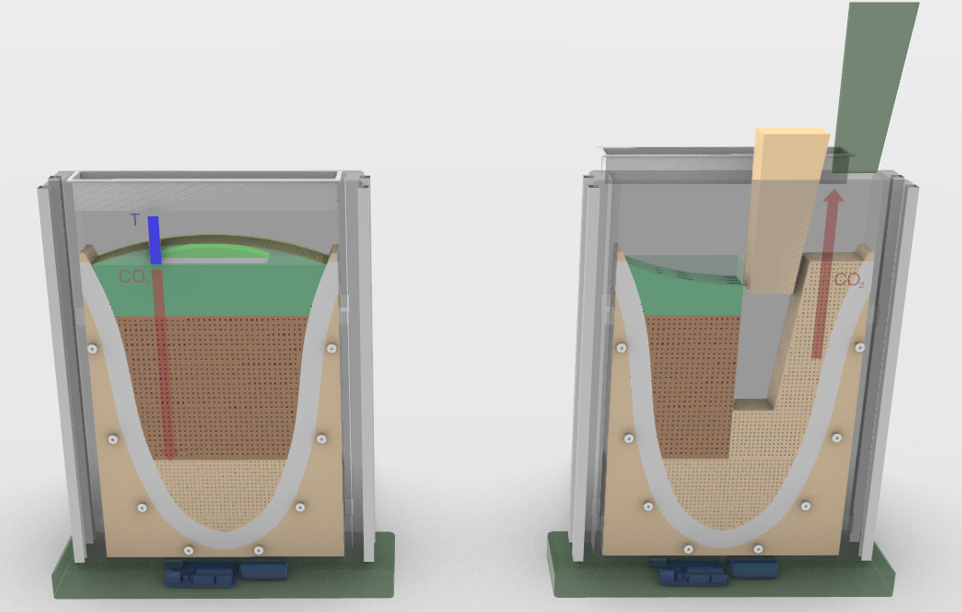

To address the challenge, fablab.tirol recommended a four-step solution. Step 1 was the EDIH Design Sprint in March 2023, which translated the challenge into concrete specifications. This took place in collaboration with SonntagPlus, the state of Tyrol, the Kaunergrat and Karwendel nature parks, and the environmental education association natopia. Step 2 followed with the EDIH Tech-Prototyping Bootcamp (July–November 2024), covering research and tech scouting, work with microelectronics and sensors, CAD design, testing of various 3D-printing materials and morphologies, laser cutting, and CNC milling. The result was a proof-of-concept prototype – PEAT 1.0 – presented publicly for the first time at the Tyrolean Landhaus open day on October 26. Feedback led to insights for the next phase: it became clear that two physical models were best suited for educational mediation – one showing a vital moor and its growth, the other a drained peatland and the effects of renaturation measures like sheet piling. Step 3, running from December 2024 to February 2025, focuses on developing a scalable Minimum Viable Product (PEAT 2.0) using similar technologies and presenting it at public events. Lessons learned will inform final adjustments. The overarching goal is not just to build a prototype, but to make the model available to educational institutions. Therefore, Step 4 – starting in April 2025 – marks the beginning of small-scale production of PEAT 3.0, financed through product revenue and independent of EDIH funding.

Result

The Tech Design Sprint laid the foundation for PEAT by clarifying the educational goals, key messages, target groups, and technical requirements for the moor models. In the “Problem Space,” relevant conditions were analyzed, followed by idea generation in the “Solution Space.” Selected solutions were digitally developed, presented to experts, and refined based on their feedback. fablab.tirol supported the process with expertise in innovation, digital fabrication, IoT, and sensor technologies.

In the following Tech-Prototyping Bootcamp, the first physical prototype – PEAT 1.0 – was developed from a digital model. Initial attempts to simulate peatland layers using 3D-printed, sponge-like structures proved impractical, so the focus shifted to creating an interactive, reduced, and understandable model of peatland in its natural, drained, and renatured states. PEAT 1.0 was publicly tested during an open day, and feedback led to the creation of PEAT 2.0, which consists of two separate models: one showing a vital, growing moor and the other illustrating drained peatland and the effects of renaturation with sheet piling. Features like a servo-controlled water level mechanism and a capacitive CO₂ sensor were added for better demonstration. After testing at various events, feedback was incorporated into PEAT 3.0 – a scalable, market-ready version, now being produced in small series by a professional model maker.